Modernizing cement manufacturing in China leads to

2022.11.17 The cement manufacturing process mainly includes four steps: resource extraction, raw material preparation, clinker calcination, cement grinding 17, 18, and

More

Process technology for efficient and sustainable cement production ...

2015.12.1 Abstract. Over the years technology in the cement industry has been further developed with a growing focus on sustainable, cost- and energy-efficient

More

(PDF) Analysis of material flow and consumption

2015.8.1 equipment used in cement production are electrical motors, pumps, compressors, transformers, furnaces, fans, blowers, con- veyors,

More

Cement processing equipment Schenck Process

Weighbridge for Rail Loading of Cement. At a glance: feeding alternative fuels in Cement. Schenck Process alternative fuel PSP handling and feeding system provides a reliable

More

The Cement Manufacturing Process - Thermo

2023.12.20 In 2022, U.S. portland cement production increased slightly to an estimated 92 million tons, and masonry cement production increased to an estimated 2.5 million tons, according to the U.S.

More

Production of cement and its environmental impact

2023.1.1 This chapter deals with cement manufacture, cement properties, types of cements, blended cements and life cycle assessment of different types of cements.

More

The digitization work of cement plant in China - ScienceDirect

2023.11.1 The construction of China's intelligent cement factory is based on the systematic solution to the actual needs of production control existing in the cement

More

Cement Manufacturing—Technology, Practice, and

2021.11.17 The primary cement manufacturing process involves the mining of raw materials, mainly limestone and clay, which are used in cement manufacturing. In most

More

Cement - Extraction, Processing, Manufacturing Britannica

Cement - Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as

More

Cement Manufacturing—Technology, Practice, and

2021.11.17 During the twentieth century, cement manufacture spread worldwide. By 2019, India and China have become the world leaders in cement production, followed by Vietnam, the United States, and Egypt. The primary cement manufacturing process involves the mining of raw materials, mainly limestone and clay, which are used in cement

More

Graph Writing # 102 - Stages and equipment used in the cement

2022.8.4 The heated mixture is then smashed in a grinder after being bagged. According to the second diagram, the cement is used in concrete production where a fixed quantity of water, cement, sand and gravel (small stones) are mixed together. 15% of cement is used along with 10% of water, 25% of sand and 50% of gravel.

More

Process technology for efficient and sustainable cement production ...

2015.12.1 Electrical energy only comprises between 10 and 15% of the overall energy demand for cement production but is a notable cost driver [4], [5].Over the last decades the average specific electrical energy consumption has decreased (Fig. 3) [6].However, there are counteracting effects: CO 2-emissions can be significantly

More

IELTS Academic Writing Process Diagram Sample: Cement and concrete ...

2021.10.12 The production of concrete, unlike that of cement, requires no complex machinery and is done by pouring four different materials into a concrete mixer. Half of the mixture is made up of gravel, and the other half includes 10% water, 15% cement, and 25% sand. All these materials are mixed in a container that rotates clockwise in order to make ...

More

Modernizing cement manufacturing in China leads to

2022.11.17 NSP rotary kilns started to account for more than 10% of the market share in 2001, and China’s national cement production peaked in 2014. Therefore, 2001 and 2014 are selected as typical years ...

More

MUHAMMAD ROHAN AMIR - Outreach Core Team

3. Interacting with the machinery and equipment used in cement production provided me with insights into their functioning, maintenance, and troubleshooting. I learned about different types of crushers, mills, rotary kilns, and other equipment employed in the cement manufacturing process. 4.

More

Types of Concrete Equipment for different project applications

2022.4.27 Concrete mixers can be divided into two broad categories Batch Mixer and Continuous Mixer. Continuous mixers are used in massive construction sites such as, for construction of dams, bridges, etc., which involves the use of large masses of concrete and also requires continuous flow of concrete. Batch mixer is one of the most common types

More

Cement - Extraction, Processing, Manufacturing Britannica

Extraction and processing. Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators.. The

More

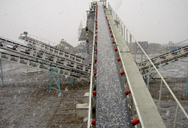

Important Equipments Used in Cement Manufacturing Plants

2022.7.20 Pulley is a mechanical equipment mostly used to drive the belt or change the direction of the belt in the conveyor system in a cement plant. Therefore, the quality of the pulley plays a great role ...

More

Development of a Mixer for Concrete Production

American Journal of Engineering and Technology Management. Vol. 2, No. 3, 2017, pp. 20-24. doi: 10.11648/j.ajetm.20170203.11. Abstract: In an attempt to improve the production of concrete and make its mixing easy, a 700 mm × 530 mm drum size of a concrete mixing machine was designed and fabricated.

More

考官Liz小作文范文合集10:流程图——工序图(如何制作水泥 ...

2019.11.14 考官Liz小作文范文合集10:流程图——工序图(如何制作水泥和混凝土). The diagram below shows the stages and equipment used in the cement-making process, and how cement is used to produce concrete for building purposes. 范文. The diagrams illustrate the way in which cement is made and how it is then used in the ...

More

Analysis of Raw Mill Machines Maintenance in

2020.5.30 The machines used in cement production at the factory include raw mill machines, kiln machines, and cement mill machines. ... effectiveness of the machinery and equipment. It can be seen from the ...

More

IMPACTS OF CEMENT INDUSTRY ON ENVIRONMENT

2019.7.8 The heavy machinery and large fans used in various parts of the cement manufacturing process can give rise to noise and/or vibration emissions, particularly from: chutes and hoppers, any ...

More

Cement Making Machine - Cement Plant Equipment Supplier

It is a kind of grinding equipment that used to grind the calcined cement clinker then make them reach the particle fineness requirement of the finished cement product. It is the core equipment of the last step in the cement production process. The cement mill we usually used in cement plants includes cement vertical mill, cement ball mill ...

More

Technological Energy Efficiency Improvements in Cement Industries

2021.3.30 The cement industry is highly energy-intensive, consuming approximately 7% of global industrial energy consumption each year. Improving production technology is a good strategy to reduce the energy needs of a cement plant. The market offers a wide variety of alternative solutions; besides, the literature already provides reviews of

More

Analysing the Primary Influential Factors in Cement

2022.9.29 Outcomes indicate that capital investment, quality control, and machinery and equipment maintenance are the influential primary factors in cement production. The result of this study may help ...

More

雅思小作文分享(流程图) - 知乎

2020.8.29 雅思小作文分享(流程图). 流程图1:The diagram below shows the stages and equipment used in the cement-making process, and how cement is used to produce concrete for the building process. Summarize the information by selecting and reporting the main features, and make comparisons where relevant. The first diagram

More

Cement raw materials production - Cement Plant, Cement Equipment

We provide customers with a variety of cement plant equipment and optimize the combination of various types of cement grinding mill to meet the needs of different processes. cement ball mill. Feeding size: ≤25mm. Capacity: 0.65-615t/h. vertical cement mill. Feeding size: ≤1100mm. Capacity: 5-200m³/h. raymond mill.

More

Senior Engineer - Misr Beni Suef Cement CO. - LinkedIn مصر

As a senior engineer at Misr Beni Suef Cement, one of the leading cement production companies in Egypt, I apply my mechanical engineering skills and knowledge to design, develop, and improve the plant's machinery and equipment. I use 3D computer-aided design (3D CAD), AutoCAD, and SOLIDWORKS to create and modify models, drawings, and

More

(PDF) Analysis of material flow and consumption in cement production ...

2015.8.1 The results show that approximately 2.48t, 4.69t, and 3.41t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages ...

More

Volume 3, Issue 5, November 2013 Study of Processing

2014.1.14 production and quality. India today is the second largest cement ... Study of Processing and Machinery in Cement Industry B.T.D.PRAVEEN VARMA, K.P.SIRISHA B.Tech, Department of mechanical engineering, SCET, Narsapur-534275 ... A raw mill is the equipment used to grind raw materials into “raw mix" during the manufacture of cement.

More

What Equipment is Used for Cement Manufacturing? - Prater

2024.1.16 Because raw coal is still used in cement manufacturing, equipment that can grind coal onsite is necessary for most cement plants. As with the actual milling of cement, manufacturing equipment used to break down the coal requires mechanisms with airlock capabilities. These must be able to handle capacities from 10-100 tons hourly.

More

Machinery and equipment - Die Europäische Kommission

2014.10.31 machinery and equipment, except for transport equipment. This sector provides equipment for use in many mining, manufacturing, energy and construction sectors, as well as producing domestic appliances. Furthermore, the machinery and equipment manufacturing sector covers arms and ammunition, whether for military or sporting uses,

More

Modeling operational cement rotary kiln variables with

2022.10.20 1. Introduction. Although the cement industry globally is one of the most important parts of the economic sector, cement production is an extremely CO 2 emission process. Several investigations have been conducted to reduce cement production issues (Chipakwe et al. Citation 2020).They were focused mainly on cement chemistry, and few

More

Construction Machinery SpringerLink

Specialized machinery and equipment used in building construction (e.g., machinery for roadworks and pipe-laying) 6. Equipment for installation, finishing work, and maintenance ... Batch production concrete mixing plants are used on sites where the produced concrete mixʼs composition often needs to be changed, while continuous production ...

More

Concrete Plant - an overview ScienceDirect Topics

2007.6.5 The contribution from the concrete plant to the CO footprint of concrete structures is minor compared with that of the cement production. By using water for power generation, people have worked with nature to achieve a better lifestyle. The mechanical power of falling water is an age-old tool. As early as the 1700s.

More

The digitization work of cement plant in China - ScienceDirect

2023.11.1 In recent years, China's cement industry has always taken reducing carbon emissions as its core goal, studied the carbon emission factors of cement process through intelligent means, and explored the carbon peak and carbon neutralization path of cement industry [15].With the increasingly stable cement production, the demand for high-quality

More

Cement Plant Equipment Technologies for more production

2019.8.8 The Clinker Plants is up to 50 TPD to 1000 TPD clinker cement plants. 4. Rotary Kiln Plants: Cement Plant’s unit offers high-quality Rotary kiln Cement plants and gives innovation, best quality ...

More

Cement Manufacturing Process: 6 StepsTo Make Cement Cement Equipment

2020.1.27 In the raw meal grinding production, the cement raw materials will be ground into finer size to make sure good mixing. In this stage, there are two types of the raw mill to choose, the vertical cement mill uses the pressure leaked by cylinder to crush the passing materials. The cement ball mill use balls to grind the materials. From now on, the ...

More

The Cement Manufacturing Process - Thermo Fisher Scientific

2023.12.20 In 2022, U.S. portland cement production increased slightly to an estimated 92 million tons, and masonry cement production increased to an estimated 2.5 million tons, according to the U.S. Geological Survey 2023 Cement Mineral Commodity Summary. The overall value of sales of cement was about $14.6 billion, with an

More